JG Series Air Srteam Dryer

JG Series Air Srteam Dryer

>> Applications

This dryer is suitable for the raw materials that contains high moisture and appear paste state and other raw materials that can not be dried with other drying methods. For example, copolymer of vinyl acetate and chlorothymol, cellulose acetate, catalyst, C.M.C., CT-1 resin, burnt plaster, electrolytic manganese dioxide, anthraquinone ammonium sulphonate, fluor, diatomaceous, silica gel catalyst, born powder, potassium perchlorate sulfonamide, synthesis resin, active gluten, active argil, chemical filter cake, titanium dioxide, decanoic acid, copper sulphate, Aluminum sulphate, sodium sulphate, calcium phosphate, starch,  dyestuff, calcium citrate, coal earth, cement, aluminum hydroxide, barium hydroxide, slurry of calcium carbonate, residue of sludge, organic compounds, ferric oxide, organic fuel, maize albumen feed, mica powder, medicine, dyestuff, paper pulp of potassium prodromata, lees residue and so on.

dyestuff, calcium citrate, coal earth, cement, aluminum hydroxide, barium hydroxide, slurry of calcium carbonate, residue of sludge, organic compounds, ferric oxide, organic fuel, maize albumen feed, mica powder, medicine, dyestuff, paper pulp of potassium prodromata, lees residue and so on.

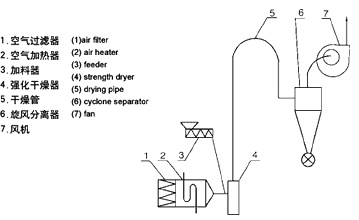

>> Principle

IAir stream dryer can remove moisture from the surface of raw materials of

granules or powder that are easy to dehydrate. Under the air stream drying

process; the quality of finished products can be controlled to the best because

of raw material stays a short time. The dryer of our company is developed on

the basis of basic spec to add a reinforced device of steeples speed exchange.

When the humidity raw material is fed through screw, it is mixed with air fully and

is broken and pushed by rotating knives, the surface of raw material is broken to

fine granule. It moves to the outlet at the same time of drying. Finally it enters into

drying pipe under the absorbing of air force, it is dried further there. The humid

and heavy granule that is not absorbed by air is broken and dried continuously till

entering the drying pipe.

>> Technical parameters (calculated based on maize)

Spec |

Moisture to be evaporated (calculated based on the surface moisture) |

Power(kw) |

Area to be occupied

(m2) |

Height(m) |

| JG50 |

50 |

10 |

20 |

9 |

| JG100 |

100 |

20 |

32 |

11 |

| JG200* |

200 |

31 |

40 |

11 |

| JG250* |

250 |

32 |

64 |

13 |

| JG500* |

500 |

54 |

96 |

13 |

| JG1000* |

1000 |

135 |

120 |

15 |

| JG1500* |

1500 |

175 |

200 |

16 |